Obscuration, Unsatisfactory Bentonite and Sulfur Dioxide Strikes Again! – Testing Times May 2017

Introduction

This month we look at some more curly issues we’ve received in the lab. Helping to solve them has involved some intricacies of testing and we’ve had to call upon our many years’ experience in sorting out some of these problems in our own laboratories.

Sulfur dioxide test problems – again!

Many wineries do some of their own testing, where possible. We support them to do this by offering apparatus, reagents and, if necessary, advice on troubleshooting and ways to improve the performance of the test.

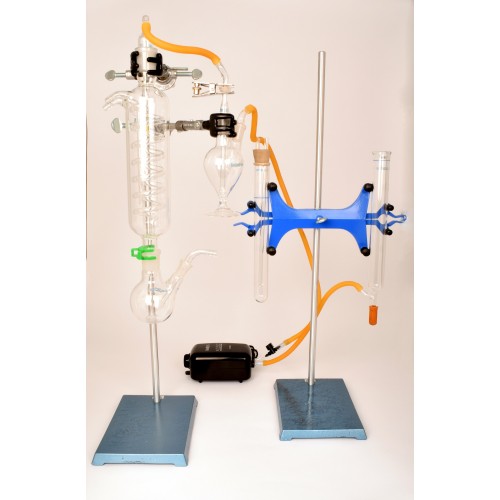

We recently had a winery that was getting abnormal duplicate sulfur dioxide results. They were using the traditional oxidation/aspiration setup (see Photo below) and had two sets of apparatus working side by side, however testing the same wine at the same time in the two rigs was giving very different results. As anyone who uses these rigs knows, they can be slightly temperamental and there are potentially several factors that could cause the discrepancy.

The customer had a good setup and had checked that the air flow rate coming out of the vacuum pump was correct by the use of a soap bubble flow meter. We suggested ensuring the bubbling in both round bottom flasks and both pear shaped flasks looked the same. This is a critical issue as sometimes a leak in the tubing or an ill-fitting glass joint can cause leaks that prevent sulfur dioxide in the sample being aspirated through the system. The operator was happy this was correct.

By doing some more trials on a standard sulfur dioxide solution it was obvious that the correct results were not being obtained. The next thing to check was the receiving solution in the pear shaped flasks. This is a hydrogen peroxide solution at a dilution of 0.3%. It is very easy for this solution to lose its strength and then not be able to “capture” the sulfur dioxide, which is what was happening in this instance A fresh hydrogen peroxide solution was made – and voilà! The correct, duplicate results were obtained.

The 0.3% hydrogen peroxide is normally made in the winery laboratory from the concentrated 30% solution. We supply the 30% solution to customers as it is very stable; a 0.3% solution is quite unstable and so we don’t supply it. The winery lab should replace the 0.3% hydrogen peroxide regularly – at least once a month to ensure the most accurate results.

Unsatisfactory bentonite fining trials

A customer brought in a wine for a heat stability test. The winemaker had done bench trials with the wine and had determined what level of bentonite addition was required. This was approximately 4 times higher than usual. We performed the Heat Stability test on the treated sample but found that the test failed – that is, after heating for the required six hours at 80oC the wine was cloudy.

As the level of bentonite added was much higher than normal, this result was a surprise. After discussions with the customer it was determined that the bentonite used for the trials for this wine was from a new supplier, was of a more granular style and hadn’t been used in the winery previously.

So the winemaker bought in some of the previously used powdery type bentonite and repeated the trials and got similar results to what was normally expected. This time the treated wine passed the heat stability test at the much lower level of bentonite addition.

The following trials to uncover the reason for the difference between the two products were suggested:

-make the 2 bentonites up with the same water

-prepare the bentonite exactly as per the manufacturer’s requirements, particularly for swelling time.

-use the same wine in each of the 2 trials

-don’t use other products in the wine at the same time

-decide on an acceptable turbidity in NTUs that is consistent for the wine style

Bentonite fining is a critical exercise that enables the wine to be placed in the market place in a sound and stable condition and should be taken very seriously. And when changing suppliers of winemaking ingredients always be on the lookout for unusual effects that may occur in the winemaking process.

Organise your Bentonite Fining Trial today

Obscuration

This is not a comment on current politics in Western democracies, but the technical use of the word when it comes to measuring alcohol content.

Wine Science degree students should have come across this term in their studies. It usually refers to the effect of substances (other than ethanol) in wine, on the measurement of density, typically by hydrometry. Substances in wine such as sugars, glycerol, acids and colouring compounds affect the ability to measure alcohol accurately by hydrometers.

This is well known in the wine industry and has given rise to several ways of measuring alcohol in wine including:

-distillation and hydrometry

-distillation and pycnometry

-ebulliometry

-near infra-red spectrometers

-High Performance Liquid Chromatography (HPLC)

-Gas Chromatography (GC)

With the increased popularity of ‘craft’ beer, cider and spirits, we have been very busy testing these new products, firstly for winery customers who have branched out and produced some of these exciting new products, and also for many new entrants to the fermented beverage industry. Obscuration is an issue for many of them because they typically measure alcohol in these non-wine products by hydrometry.

A word of caution: the allowed variation for alcohol label statements is quite different for beer, cider and spirits compared to wine. To quote Food Standards Standard 2.7.1 Labelling of Alcoholic Beverages and Food containing Alcohol:

“The (alcohol) statement…must…be accurate to within the limits specified in column 2 of the table below:

| Column 1 | Column 2 |

| Beer, cider, perry | 0.3% alc/vol |

| Spirits, liqueurs, fortified wine… | 0.5% alc/vol |

| Wine and fruit wine… | 1.5% alc/vol |

We recently did an obscuration exercise for a spirits producer who had three different products to test. To do this we tested the neat sample, and then distilled the sample and tested alcohol on the distillate, this of course not possessing any obscurants. Interestingly, two of the products showed very little difference between hydrometry results on the neat sample and the lab distilled sample. But one sample had a difference well over 1% alc/vol which is well outside the accuracy required by the labelling regulations above.

And worse still, the Australian Tax Office has its own testing requirements: for beer and spirits the accuracy required is 0.2% alc/vol. When questioned, the ATO Excise section representative admitted that their requirements differed from Food Standards and advised that “that’s just how things are”!

So, beware of obscuration, and for such an important test as alcohol, our recommendation is to talk to a professional consulting lab for this measurement for any beer, cider or spirits you are selling.

Contact your nearest Vintessential Laboratory for advice.

Greg Howell founded Vintessential Laboratories in 1995; he can be contacted by email on [email protected]/. More articles on related topics are available on the Vintessential website: www.vintessential.com.au/resources/articles/